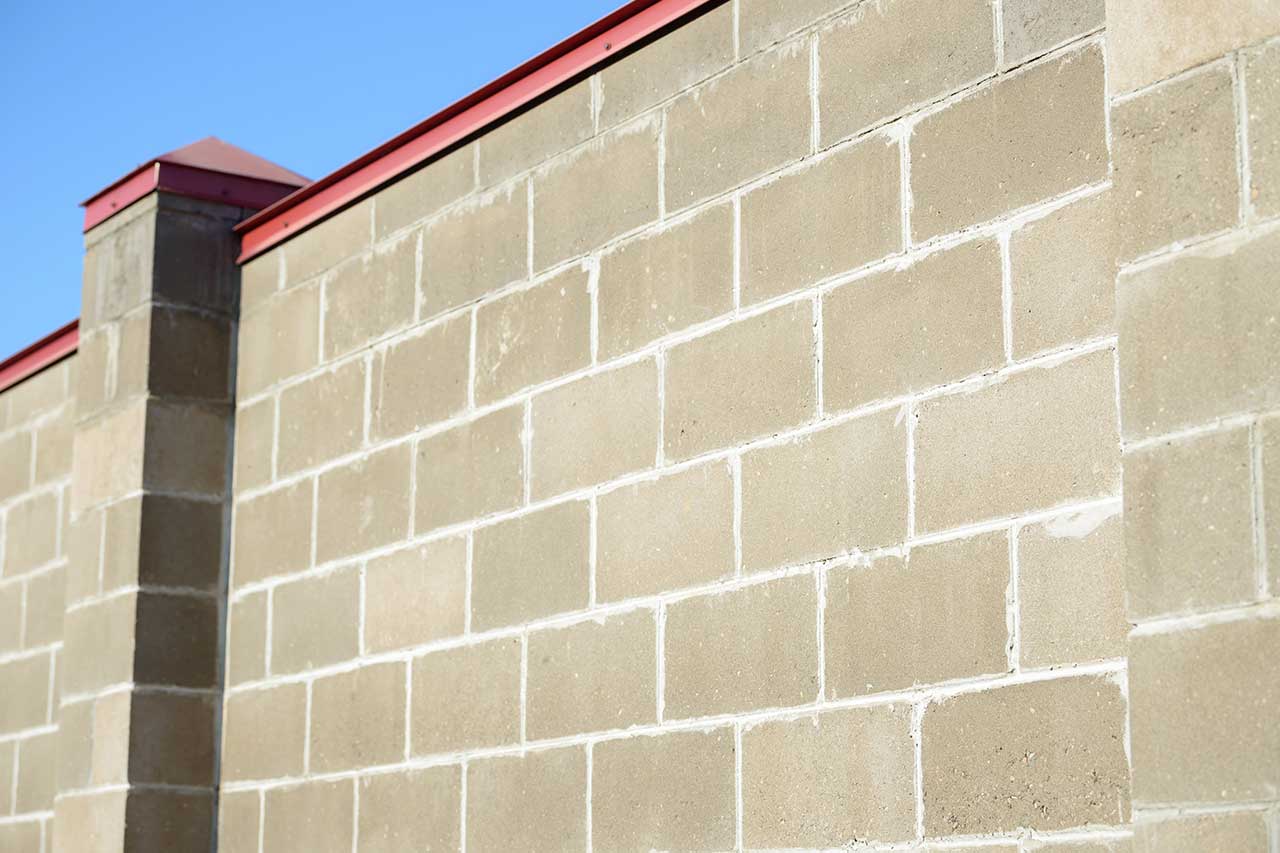

In the realm of culinary spaces, the industrial kitchen stands as a testament to functionality, durability, and a raw aesthetic. At the heart of this design ethos often lies the humble cinder block wall – a structural element that, when thoughtfully integrated, can define the character and performance of a professional cooking environment.

Looking ahead to 2025, The Construction Zone Ltd, a forward-thinking design and construction firm, is pioneering innovative approaches to industrial kitchen design. Their vision embraces the inherent strengths of cinder block walls while pushing the boundaries of their aesthetic potential.

The Enduring Appeal of Cinder Block Walls in Industrial Kitchens

Cinder blocks, also known as concrete masonry units (CMUs), have long been a staple in industrial construction. Their popularity stems from a combination of practical advantages:

- Durability: Cinder blocks are incredibly robust, capable of withstanding the rigors of a high-volume kitchen. They resist impact, heat, and moisture, ensuring longevity even in demanding environments.

- Fire Resistance: An essential safety feature, cinder blocks offer excellent fire resistance, helping to contain potential kitchen fires and protect the overall structure.

- Sound Insulation: Industrial kitchens can be noisy places. Cinder block walls provide effective sound insulation, reducing noise pollution and creating a more comfortable working environment.

- Cost-Effectiveness: Compared to other wall-building materials, cinder blocks are relatively inexpensive, making them an attractive option for budget-conscious projects.

- Structural Integrity: Cinder block walls provide significant structural support, capable of bearing heavy loads and resisting lateral forces.

- Ease of Maintenance: Cinder block walls are easy to clean and maintain, requiring minimal upkeep to keep them looking their best.

VIEW PRODUCT ADD TO CART

The Construction Zone Ltd’s 2025 Design Philosophy: Elevating the Cinder Block

While cinder block walls have traditionally been viewed as purely utilitarian, The Construction Zone Ltd is reimagining their role in industrial kitchen design. Their 2025 vision focuses on:

- Aesthetic Integration: Moving beyond the plain, gray aesthetic, The Construction Zone Ltd explores various surface treatments to enhance the visual appeal of cinder block walls.

- Functional Enhancement: The design incorporates features that maximize the utility of cinder block walls, such as built-in storage, equipment mounting, and integrated utilities.

- Sustainability: The Construction Zone Ltd prioritizes sustainable practices, using recycled cinder blocks and eco-friendly finishes to minimize the environmental impact of their designs.

VIEW PRODUCT ADD TO CART

Aesthetic Transformations: From Utilitarian to Striking

The Construction Zone Ltd employs several techniques to transform the aesthetic of cinder block walls:

- Painting and Coating: Applying a coat of paint or epoxy coating is the simplest way to alter the appearance of cinder block walls. The Construction Zone Ltd utilizes a range of colors and finishes, from bright, vibrant hues to muted, industrial tones. Epoxy coatings provide added durability and resistance to chemicals and moisture.

- Texturing: Adding texture to cinder block walls can create a more visually interesting surface. Techniques include applying stucco, creating a rough trowel finish, or using textured paint rollers.

- Cladding: Cladding involves covering the cinder block wall with another material, such as brick, stone, metal panels, or wood. This allows for a wide range of aesthetic possibilities, from a rustic, farmhouse look to a sleek, modern design.

- Polishing: Polishing cinder block walls can reveal the natural aggregate within the concrete, creating a unique and sophisticated look. This technique is particularly effective when combined with staining or sealing.

- Glazing: Applying a glaze to cinder block walls can add depth and dimension to the surface. The Construction Zone Ltd uses a variety of glazing techniques to create different effects, such as a subtle sheen or a dramatic, high-gloss finish.

- Murals and Artwork: Cinder block walls provide a blank canvas for murals and other forms of artwork. The Construction Zone Ltd collaborates with local artists to create custom murals that reflect the unique character of each kitchen.

Functional Integration: Maximizing Utility

The Construction Zone Ltd integrates functional elements into cinder block walls to enhance their utility:

- Built-in Storage: Creating niches and shelves within the cinder block wall provides convenient storage for kitchen equipment, utensils, and supplies.

- Equipment Mounting: Cinder block walls provide a stable and secure surface for mounting heavy kitchen equipment, such as ovens, ranges, and ventilation hoods. The Construction Zone Ltd uses specialized anchors and fasteners to ensure that equipment is securely mounted.

- Integrated Utilities: Running plumbing and electrical wiring within the cinder block wall creates a clean and uncluttered look. The Construction Zone Ltd carefully plans the placement of utilities to ensure that they are easily accessible for maintenance and repairs.

- Pass-Through Windows: Incorporating pass-through windows into cinder block walls allows for easy communication and transfer of food between the kitchen and dining areas.

- Ventilation: Strategically placed ventilation blocks or openings within the wall can improve airflow and reduce the buildup of heat and moisture.

- Acoustic Panels: Integrating acoustic panels into the cinder block wall can further reduce noise levels and improve the overall sound quality of the kitchen.

Sustainability: Minimizing Environmental Impact

The Construction Zone Ltd is committed to sustainable design practices, minimizing the environmental impact of their projects:

- Recycled Cinder Blocks: Using cinder blocks made from recycled materials reduces the demand for new resources and diverts waste from landfills.

- Eco-Friendly Finishes: The Construction Zone Ltd uses low-VOC paints, coatings, and sealers to minimize air pollution and protect the health of kitchen staff.

- Energy Efficiency: Designing the kitchen layout to maximize natural light and ventilation reduces the need for artificial lighting and air conditioning.

- Water Conservation: Incorporating water-efficient fixtures and appliances reduces water consumption.

- Waste Management: Implementing a comprehensive waste management program reduces waste generation and promotes recycling.

Case Study: The Construction Zone Ltd’s "Culinary Innovation Hub"

To illustrate their design philosophy, consider The Construction Zone Ltd’s hypothetical "Culinary Innovation Hub," a state-of-the-art industrial kitchen designed for a food research and development company in 2025.

- Walls: The kitchen features cinder block walls that have been clad in a combination of stainless steel panels and reclaimed wood. The stainless steel provides a hygienic and easy-to-clean surface in food preparation areas, while the reclaimed wood adds warmth and character to the space.

- Storage: Built-in niches within the cinder block walls provide storage for frequently used utensils and spices.

- Equipment Mounting: Heavy-duty ovens and ranges are securely mounted to the cinder block walls, freeing up floor space and creating a more efficient workflow.

- Utilities: Plumbing and electrical wiring are concealed within the cinder block walls, creating a clean and uncluttered look.

- Ventilation: A high-efficiency ventilation system is integrated into the cinder block walls, ensuring proper air circulation and removing cooking fumes.

- Acoustics: Acoustic panels are strategically placed on the cinder block walls to reduce noise levels and create a more comfortable working environment.

Challenges and Considerations

While cinder block walls offer numerous advantages, there are also some challenges and considerations to keep in mind:

- Moisture: Cinder blocks can be porous and prone to absorbing moisture. Proper sealing and waterproofing are essential to prevent moisture damage and mold growth.

- Cracking: Cinder block walls can be susceptible to cracking, especially in areas with seismic activity. Proper reinforcement and construction techniques are necessary to minimize the risk of cracking.

- Aesthetics: The raw, unfinished look of cinder block walls may not be suitable for all kitchen designs. Careful planning and surface treatments are essential to achieve the desired aesthetic.

- Code Compliance: Cinder block wall construction must comply with all applicable building codes and regulations.

The Future of Cinder Block Walls in Industrial Kitchens

As The Construction Zone Ltd’s 2025 vision demonstrates, cinder block walls have a bright future in industrial kitchen design. By embracing innovative aesthetic treatments, functional enhancements, and sustainable practices, designers can transform these humble building blocks into a defining element of modern culinary spaces.

The key lies in recognizing the inherent strengths of cinder block walls – their durability, fire resistance, and cost-effectiveness – and then creatively leveraging these strengths to create kitchens that are both functional and visually appealing.

Conclusion

Cinder block walls, once relegated to the realm of purely functional construction, are undergoing a renaissance in industrial kitchen design. With firms like The Construction Zone Ltd leading the way, these walls are being reimagined as a canvas for creativity, a platform for functionality, and a testament to sustainable design principles. As we move towards 2025 and beyond, expect to see cinder block walls playing an increasingly prominent role in shaping the culinary spaces of the future.

Komentar

Posting Komentar